Direct-to-Device Phase Change Cooling

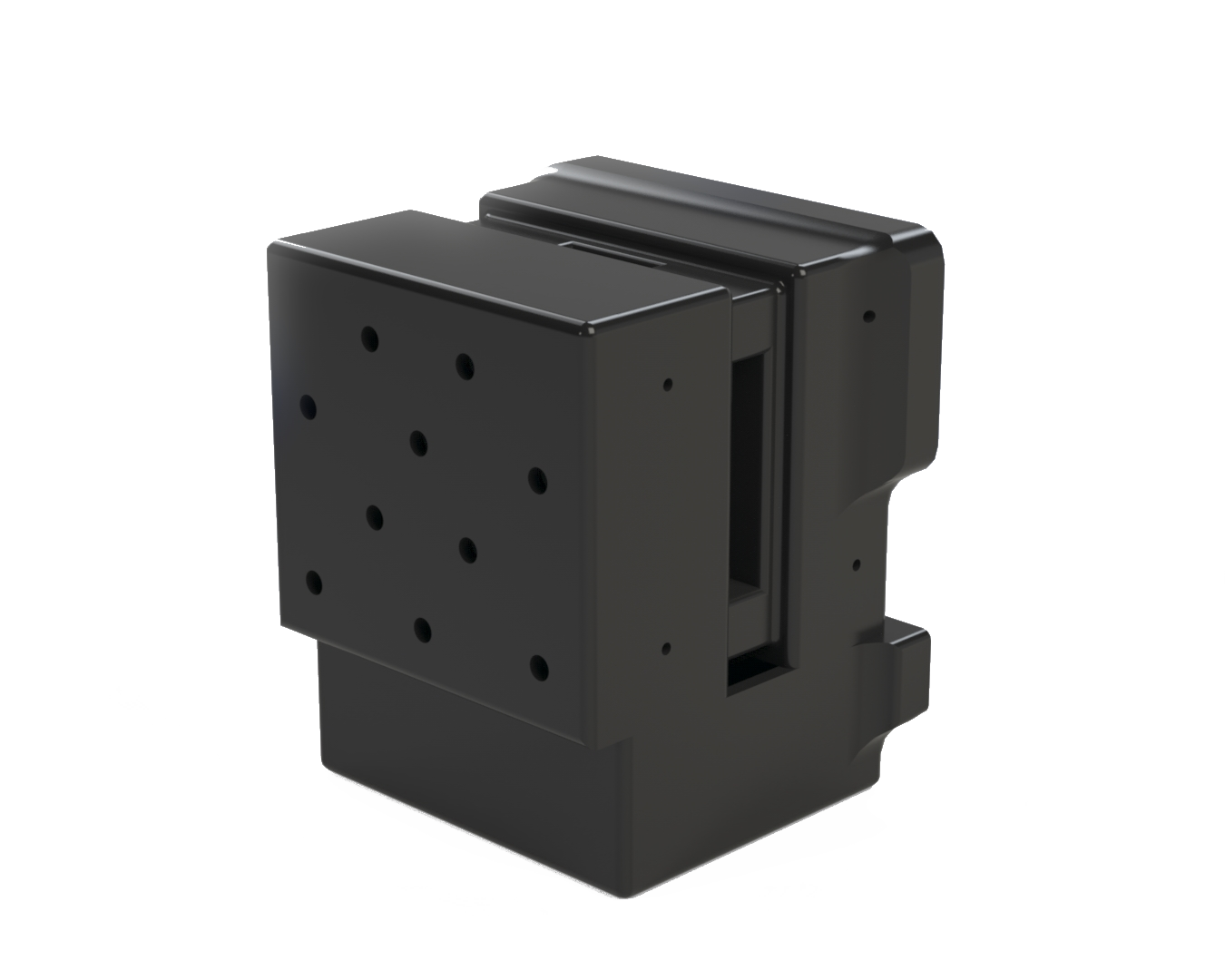

Sepolina 120

An evolution in direct-to-chip cooling: utilizing a solid medium of thermal transfer to deliver the benefits of refrigerant-based cooling. Minimizing your energy expenditures and maximizing your operational efficiency.

Function

Sepolina Has 3 Sub-Systems working together to cool your heat producing componentry:

Cooling System: A closed-loop, refrigerant based cooling system, scaled down, enclosed, and kept in proximity of the heat source requiring cooling. As all refrigerant stays within the boundaries of the cooling system, there obviously needs to be a method of transferring the heat towards the refrigerant. The next two components address that process directly.

Heatsink (Freezeblock): A heatsink to be placed in direct contact with the heat producing device(s). Designed as a platform for connection to the thermal transport loop components. As well incorporating environment isolating materials that ensure heat transfers primarily towards the thermal transport loop.

Thermal Transport Loop (Connector Loop): A series of tool-less interlocking sections, arranged in a user defined route, that bridges the gap between cooling system and the heatsink connected devices. Made of material with high thermal conductivity, with the primary goal of enabling thermal transport without incurring an energy expenditure. The thermal transport loop also incorporates environment isolating materials, to ensure thermal transfer occurs within the thermal transport loop.

Function Diagram

.png)

Cold Side

Indicated via the blue line, is the thermal transfer pathway responsible for cooling intended devices.

Within the server is a provided heatsink which attaches to the CPU/GPU or another device to be cooled. Connecting to this heatsink are the solid connectors responsible for thermal transport, which creates a path from heatsink to the rear of the server.

From the rear of the server, additional solid connectors attach to the rear door spacer manifold. Where the positioning of solid connectors is managed to maintain access to the server for any maintenance tasks.

After the rear door spacer manifold, additional solid connectors create a path to the cold side of the cooling system, within an enclosure.

This arrangement creates the thermal transfer pathway, which cools the attached devices.

Hot Side

Indicated via the red line, is the thermal transfer pathway responsible for exhausting heat.

Starting with the hot side of the cooling system, a separate solid connector loop transfers the heat within the coolant to an external environment.

Prior to complete exhausting, there is a transference towards the exhaust heat recovery system for generation of electricity. By separating the cooling side from the exhausting side, each loop can operate in the optimal window for their intended tasks.

Post exhaust heat recovery system, the remaining heat is exhausted to the external environment.

This arrangement creates the thermal transfer pathway, which exhausts the transferred heat.

Thermal Transport Material Comparison

| Material Property | Air | Water | Sepolina Thermal Transport Material | |

| Density (ρ) (Units - kg/m^3) | 1.19 | 997 | 2800 | 9000 |

| Specific Heat Capacity (Cp) (units - 10^3 J/Kg°C) | 1.005 | 4.186 | 0.800 | 0.350 |

| Volumetric Heat Capacity (ρ.CP) | 1.195 x 10^3 | 4.173 x 10^6 | 2.00 x 10^6 | 3.15 x 10^6 |

| Thermal Conductivity (W/m°C) | 0.026 | 0.61 | 160 | 340 |

| Requires Energy for Thermal Transportation | Yes | Yes | No | No |

Each material has physical properties that help determine selection as a medium of thermal transportation, such as the lower density of air requiring less energy to move, or the higher heat capacity of water holding more heat per volume moved. Both materials while capable of serving as coolant and medium of thermal transport, have properties which present reason for use as only a coolant. Namely the fact that air and water both require an energy expenditure to move the material toward and away from the source of heat.

The possible thermal transport materials for Sepolina listed in the table above, avoid energy expenditures by maintaining continual direct contact with the source of heat and the method of cooling without motion. As well as containing material properties that enable superior rates of thermal transference. Thus, enabling the separation of coolant and thermal transport material properties into the most optimal selection for both roles.

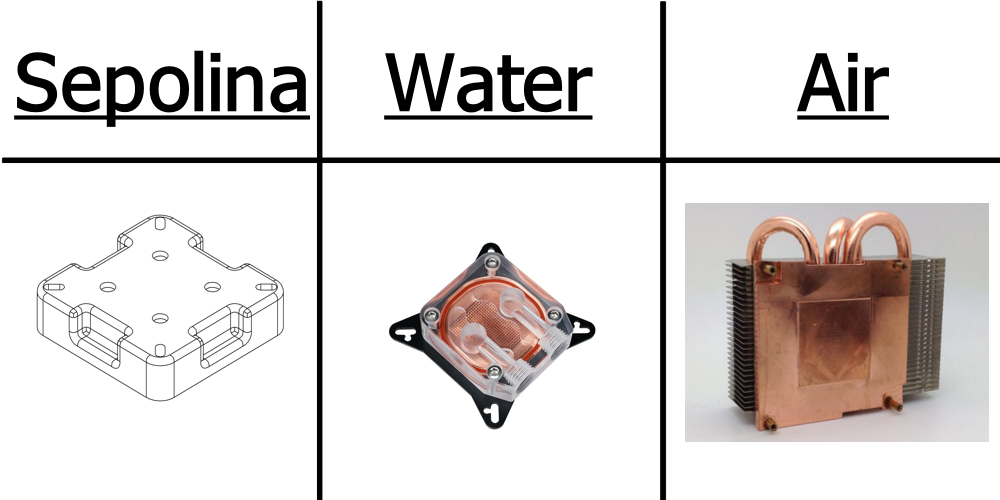

Sepolina Sub-System Analogues

Cooling System

Sepolina's cooling system is similar to these aspects of other more traditional cooling systems:

Water: The pump moves the substance responsible for thermal transfer away from the heat producing device to the primary cooling method. The radiator and fans then transfer the heat away from the thermal transfer substance and into the external environment.

Air: Fans direct airflow to remove heat stored within the heatsink, heat pipes and radiator fins.

Sepolina: Utilizing refrigerant evaporation, heat is transferred through the connector loop, from the freezeblock to the cooling system. The cooling system absorbs the transferred heat into the substance at in its coolest point in the direct expansion process. This heat converts the substance into its gas phase which is required to reinitialize the direct expansion process. The heat sent out into the external environment is only that which is created during the direct expansion process of cooling the pressurized gas, the heat from the heat producing device is absorbed in the process of converting the substance from liquid to gas.

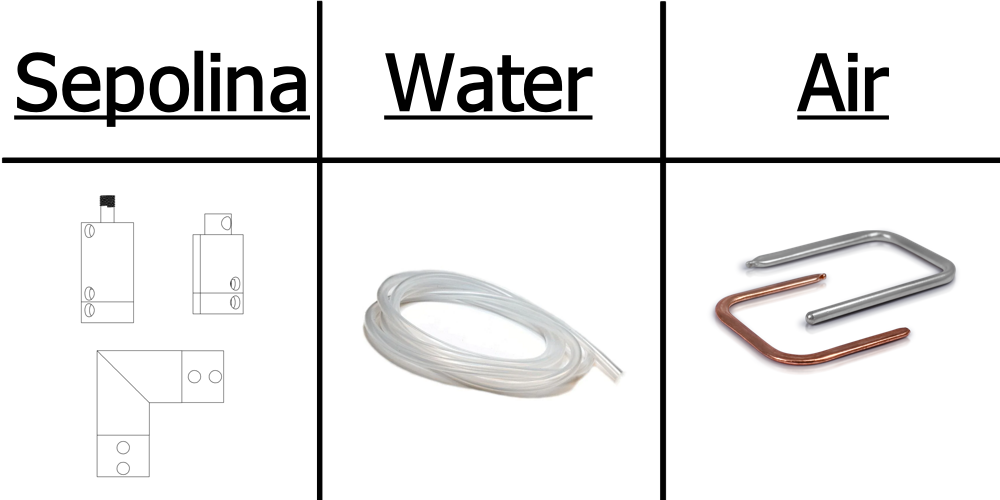

Connector Loop

Sepolina's connector loop is similar to these aspects of other more traditional cooling systems:

Water: The liquid, its flow path and the pump act as the connection between the heat producing device and the cooling system or method used. The properties of the liquid and its flow path, allow the heat transferred into the liquid from the heat producing device, to be transferred to the cooling system via the pumping device.

Air: The heatsink and/or heat pipes, connected to the heat producing device, provide a thermal transfer path from the heat producing device to the cooling method used or additional heat storage methods.

Sepolina: Individual connectors of various shapes, connected by proprietary methods, join together to make a flow path which connects the separated heat producing device and the cooling system. The connector material, with the aid of thermal interface materials, transfers heat from the heat producing device to the cooling system.

Freezeblock

Sepolina's Freezeblock is similar to these aspects of other more traditional cooling systems:

Water: The heatsink, commonly referred to as a waterblock, is used to connect the heat producing device to the method of thermal transfer, which then transfers heat to the cooling system and stores heat for later utilization.

Air: The heatsink is used to connect the heat producing device to the method of thermal transfer, which then transfers heat to the cooling system and stores excess heat for later utilization.

Sepolina: The heatsink, referred to as the Freezeblock, is used to connect the heat producing device to the method of thermal transfer, which then transfers heat to the cooling system and stores heat for later utilization.